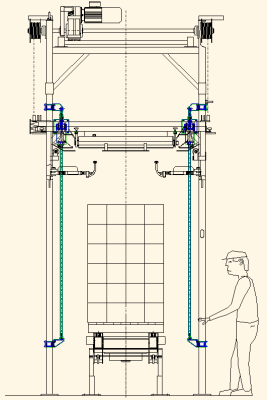

For lifting gears in the area of setting machines, unloading and packaging plants, only process-related holding systems are available in standard operation, which do not offer sufficient protection or industrial safety against unintentional lowering in certain situations. For example, lifting gears are often only held in position by drive motors with built-in brakes. Mechanical wear can cause the brakes to fall below the nominal holding torque, which in turn causes the suspended loads to drop unintentionally. With hydraulic and pneumatic lifting gears, this danger exists due to a possible sudden pressure drop in the system.

From the point of view of industrial safety, the cases to be considered are those in which persons have access to danger areas or in which a full or partial stay in the danger area is required. This often leads to faults in the production process, but also during maintenance and servicing work. If a drop of the suspended load cannot be avoided here, measures must be taken to reduce the risk. This necessary increase in machinery safety requires the retrofitting of brakes or holding devices which, according to the applicable Machinery Directive, are placed on the market separately and thus independently of the machine.

Fall protection equipment

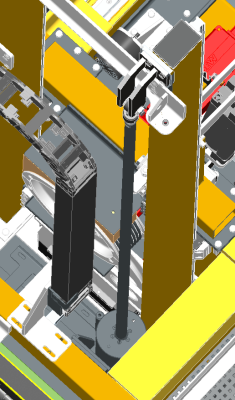

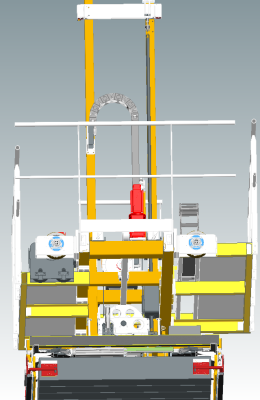

Automatic fall protection equipment for lifting gears and film hood machines

Fall protection equipment - using the example of lifting gear and film hood machine

Manual safety measures are often time-consuming and carry the risk of inadequate safety.

Our accident protection plan therefore provides for the installation of an automatically acting brake system that prevents the load from dropping inadmissibly. The systems we provide for this purpose have been designed in accordance with the 'Principles for Testing and Certification of Braking and Holding Devices' and thus comply with the currently applicable regulations.

Our accident protection plan therefore provides for the installation of an automatically acting brake system that prevents the load from dropping inadmissibly. The systems we provide for this purpose have been designed in accordance with the 'Principles for Testing and Certification of Braking and Holding Devices' and thus comply with the currently applicable regulations.