News

News of the Business Unit IMS can be found here

KELLER at the "1st HISPALYT Decarbonization Conference"

On 7 May, the "1st HISPALYT Decarbonization Conference" took place in Madrid. With our presentation on "Our vision: Decarbonization in the brick and tile industry", our colleague Rainer Hüsing once again gave an excellent presentation on KELLER's innovative strength. We received support from our colleague, Luigi Bosco from Rieter Morando, with the translation into the local language. The Spanish brick association "HISPALYT" celebrated its 50th anniversary in 2018. The association brings together around 100 manufacturers of ceramic building products.

"Doppelkopfturnier" on 24.01.2025

This year, the donation from the internal "Doppelkopfturnier" will go to the Hospizverein Ibbenbüren e.V. The association is dedicated to outpatient hospice and palliative care. Many thanks to everyone involved!

KELLER and Rieter Morando at the KazBuild in September 2024 in Almaty, Kazakhstan

From September 4 to 6, the leading construction trade fair in Kazakhstan took place at the Atakent exhibition center. The 30th International Trade Fair for Construction and Interior Design, the KazBuild 2024 in Almaty. Our participation at the KazBuild took place via the German government's foreign trade fair program. Together with Rieter Morando, the trade fair was a complete success for our company. During the three days of the fair, the KELLER booth was very busy.

Ceramic products shape our future

was the focus of this year's 27th Eurosymposium. On September 11 and 12, the KI Keramikinstitut in Meissen welcomed colleagues from all areas and production stages of ceramics. KELLER was cordially invited to contribute to the event with a presentation on energy-related topics. We gladly accepted this invitation and informed around 100 interested listeners with the topic “Transformation of the energy system - best practice: realized heat recovery concepts”. Based on two realized examples, we were able to show that KELLER provides the entire implementation of heat recovery projects. Starting with the recording and evaluation of energy flows, through project planning to the complete engineering, delivery, installation and commissioning of the plants. In addition to the Climate Protection Act, which stipulates greenhouse gas neutrality by 2045, the Energy Efficiency Act (EnEfG § 17) is increasingly focusing on measures to reduce waste heat flows and increase energy efficiency.

Further information on recording waste heat flows can be found here: https://www.keller.de/en/ics/service-products/technology-for-waste-heat-measurements/

CHINAPLAS 2024

This year, KELLER took part in the International Trade Fair for the Plastics and Rubber Industry in Shanghai from 23 to 26 April for the first time. Martin Peters, Area Sales Manager BU IMS and our representative in China, German Tech Co. Ltd., were able to hold numerous promising discussions, so that the success story of the film skiving machine can continue. The fair is the region's most important platform for showcasing the latest market trends, breakthrough technologies and innovative solutions for the plastics and rubber industry, with the 3 main themes in 2024: Smart Manufacturing, Innovative Materials and Eco-Friendly Solutions. In 2024, 321879 visitors and 4420 exhibitors were counted.

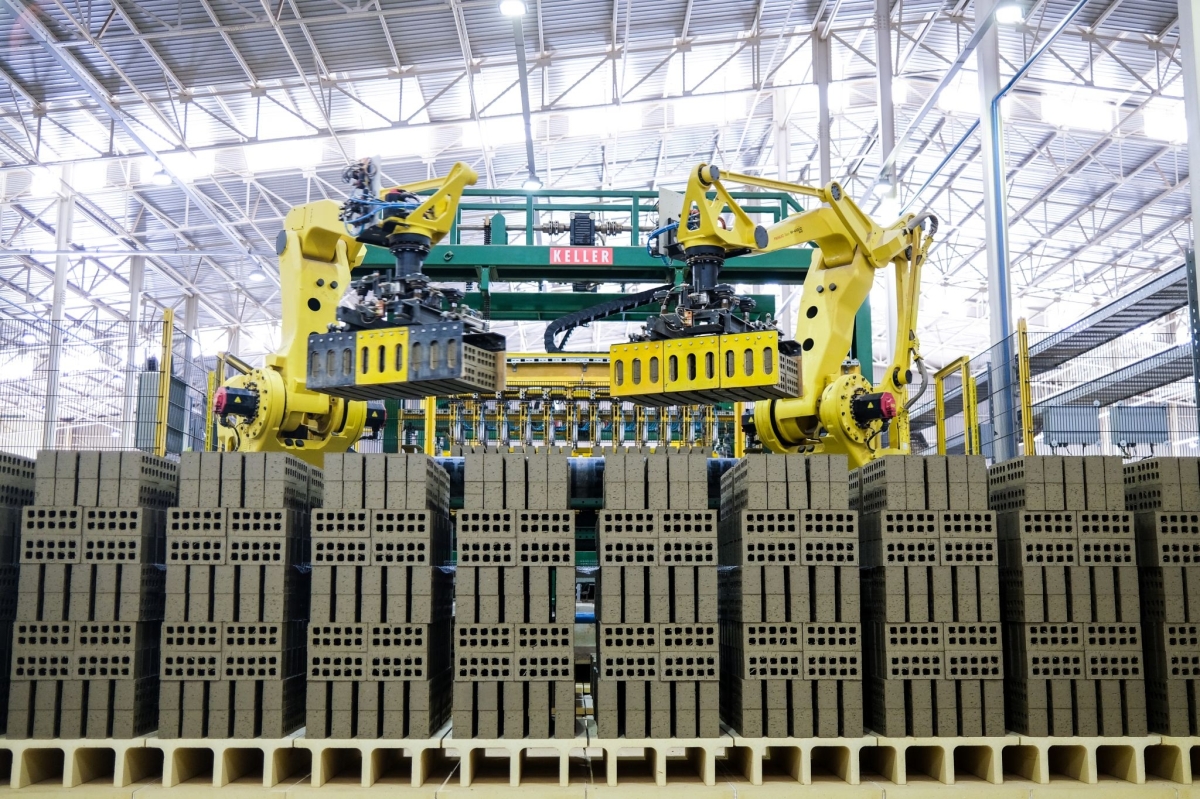

280 years of experience in the heavy clay industry

This month, the KELLER division celebrated the 150th anniversary of Rieter Morando and the 130th anniversary of KELLER - 280 years of experience in the heavy clay industry are more than enough reason to raise a glass and invite our customers to a great event in Munich.

You can find the video here: https://youtu.be/fgV5QNQUnwg?si=gVelvMto8mHvgw7t

Climate neutrality in the manufacture of heavy clay products

KELLER ICS - KELLER sees climate neutrality in the manufacture of heavy clay products and digitalisation in the brick and tile industry as the key challenges facing the sector. The KELLER technical article ‘Climate-neutral firing process 4.0 in the clay brick and tile industry’ in the current issue 01/2024 of ZI Brick and Tile Industry International explains the current status of research and development results for a climate-neutral production process and provides an outlook on further development opportunities for energy saving.

KELLER participates in the state programme

As a participant in the state programme, KELLER has signed the charter on reconciling work and care and is a reconciliation partner. The care guide person at KELLER provides initial information and orientation on the compatibility of work & care on a collegial basis and informs about external assistance and regional counselling networks.

Balancing work and care is becoming increasingly important. The number of people in need of care and thus the number of family carers is continuously increasing. The employment rate is also rising steadily. Consequently, the group of working family carers is growing. At the same time, the lack of qualified personnel continues to worsen in many companies.

There are currently 1.2 million people in need of care in North Rhine-Westphalia (NRW). Most of them are cared for at home by their relatives. In many cases, these carers are employed: An estimated 500,000 working people in NRW care for relatives, partners or friends in addition to their job. It is our responsibility as an employer to take into account the demographic development of society on the one hand and, above all, the needs of our employees who take on care responsibilities on the other.

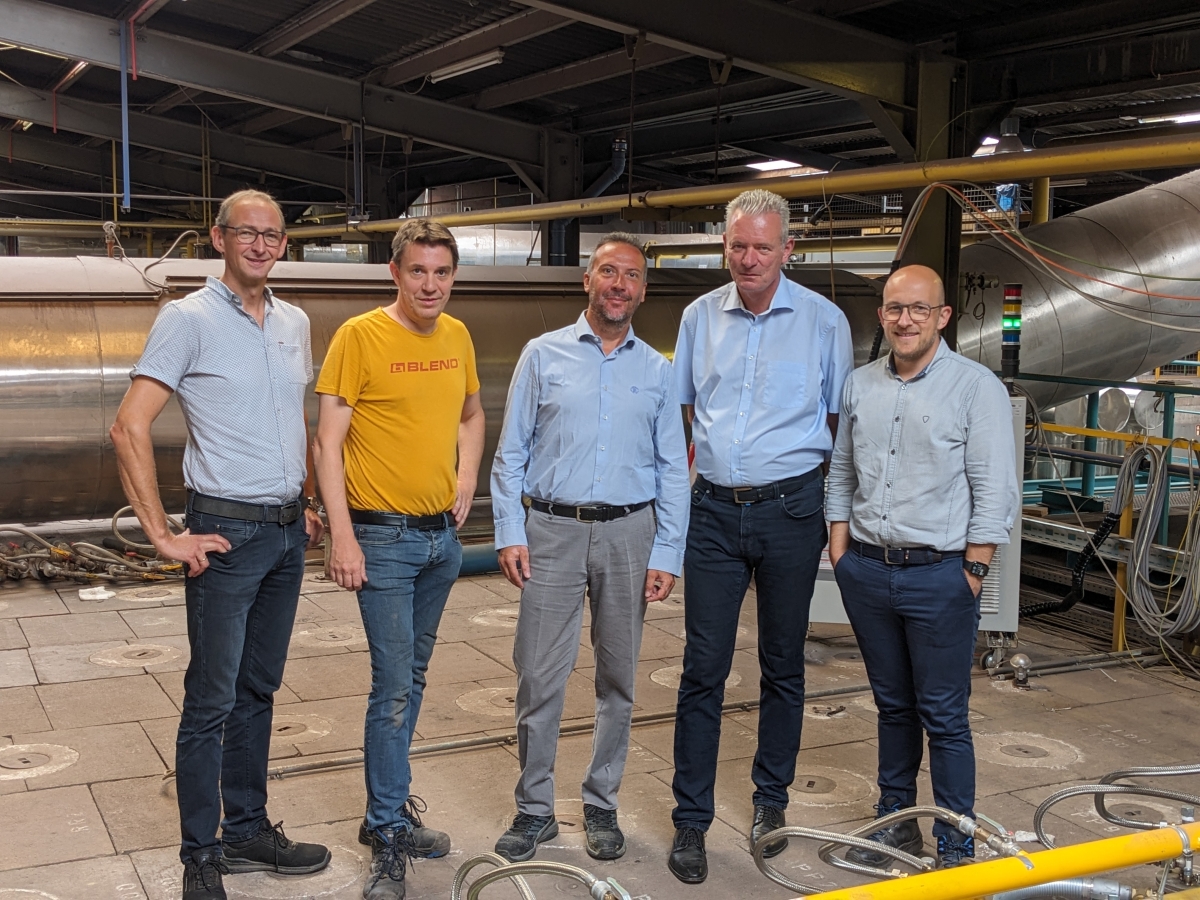

KELLER HCW has successfully conducted hydrogen firing test under real operation conditions

At the Hagemeister clinker bricks production plant in Nottuln (Germany), bricks were fired with hydrogen under real conditions in a joint project with several partners. This positive and pragmatic success places KELLER now in a position to deliver burner technology for hydrogen operation, together with the required control and safety technology. And thus, it is doing justice to its ambitious claim of increasing energy efficiency and reducing CO2 emissions in the bricks and tiles industry.

The test operation with hydrogen is part of the research project

Burning Roads 2023 - cycling for a good cause

Burning Roads 2023 - cycling for a good cause

In 2023, our colleagues Karl-Heinz Alfing and Thorsten Schnetgöke participated once again in

From Westphalia to the world

We consistently follow market requirements' - true to this maxim, KELLER HCW GmbH from Ibbenbüren in Westphalia has become an internationally sought-after machine and plant originally focussed on the brick and tile industry and today has gained experience for and today uses its experience for various other industrial sectors.

Read our contribution in the Business Forum: https://www.wirtschaftsforum.de/interviews/keller-hcw-gmbh/von-westfalen-in-die-welt

Future Day 2023

On April 27, some students got a taste of our apprenticeship professions. The nationwide campaign day (formerly "Girls'Day, Boys'Day") for girls and boys is held every school year at all general education schools for grades 5 - 9. On this day, students are given insights into various professions that are suitable for expanding the traditional, gender-specific spectrum of possible professions for girls and boys. They can take part in activities in companies, colleges and institutions and are thus encouraged to explore professions that they themselves usually do not consider. Four girls and eight boys visited KELLER. In the morning, the young people were given an insight into the professions of industrial mechanic and industrial clerk. After a small snack, at this point a big thank you to Burger Bench https://burger-bench.de/ for the great preparation, they went on to the areas of electronics technician and ceramics laboratory. It was an exciting and informative day! Many thanks to all!

April 28: World Day for Safety and Health at Work

The annual World Day for Safety and Health at Work promotes the prevention of occupational accidents and diseases worldwide. It is an awareness campaign designed to draw international attention to the scale of the problem and how promoting and creating a culture of safety and health can help reduce work-related deaths and injuries.

As an employer, we are responsible for ensuring that the work environment is safe and healthy.

EcoVadis certification

KELLER receives the EcoVadis certification in silver.

Corporate Social Responsibility (CSR) aims to firmly embed the issue of the environment and social responsibility into the company's processes, products and services. By implementing CSR, the company commits to positively impacting society and the environment while remaining economically viable. The goals are achieved with the help of employees, customers and suppliers. The provider of sustainability and CSR ratings EcoVadis today rates a network of over 75,000 companies around the world. The basis of the ratings is a documentation check carried out by EcoVadis, which is based on size, industry and country. Companies are assessed against 21 criteria in the environmental, social and ethical areas, as well as in terms of supplier relations. This year, we will continue to improve in the areas of quality, environment, labour and human rights, ethics and sustainable procurement.

KELLER HCW GmbH

Yvonne Niemeyer

Marketing

Carl-Keller-Straße 2-10

49479 Ibbenbüren, Germany

+49 5451 85-229

yvonne.niemeyer@keller.de