Foundry

You can find the industry solutions of the business unit IMS here

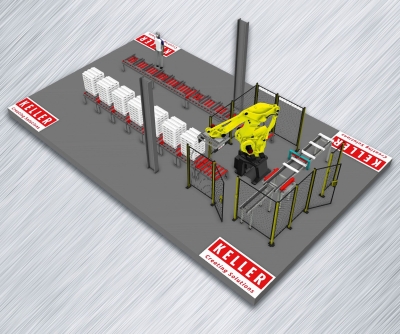

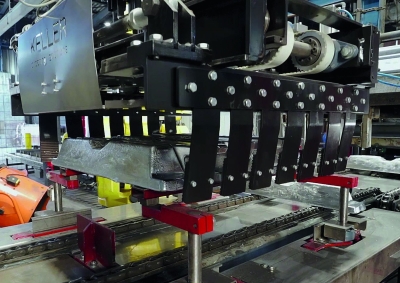

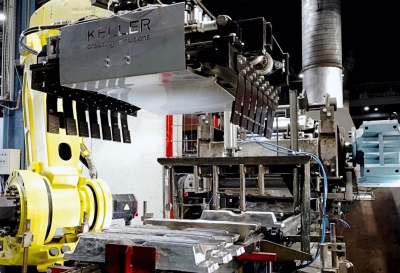

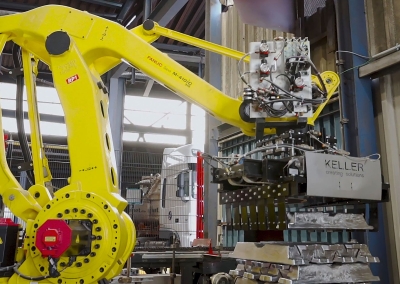

Robot-supported palletizing of aluminium ingots

By replacing a fault-prone ingot stacking system with palletizing using industrial robots, downtimes could be reduced and the speed of palletizing the 400°C hot aluminium ingots could be increased. This resulted in a significant increase in the efficiency of the plant, so that the investment costs were amortised after only a short time.